The original, the best, the inimitable.

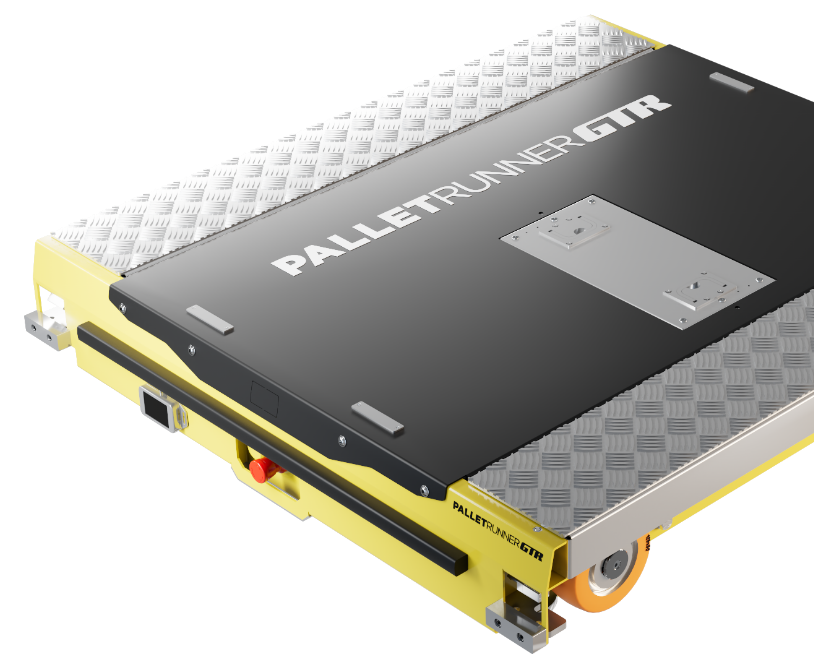

PalletRunnerGTR, welcome tomorrow

THE EVOLUTION OF THE SHUTTLE

PalletRunnerGTR is the new generation of PalletRunner shuttles designed and produced by Automha.

PalletRunner was founded in 1999 and today has more than 11,000 machines installed worldwide to guarantee a reliable, safe and high-performance product. PalletRunner is chosen by the most important manufacturers of shelves, forklifts and system integrators on the market. PalletRunner is a point of reference and the market leader in multi-depth storage systems.

THE BEST ON THE MARKET

Automha offers its customers and dealers the best of available technology and an increasingly enveloping experience. The new PalletRunnerGTR was developed in two phases:

- analysis of the market and trends of the next 10 years;

- analysis of PalletRunner’s 25 years of presence in the market, analyzing the requests, functionalities and optimization of components to provide an increasingly easy and secure user experience.

THEY CHOSE US

and many more...

WHY CHOOSE PalletRunnerGTR

Choose PalletRunnerGTR and discover how technology can transform the warehouse experience, making it simpler, safer and more sustainable. Thanks to its advanced technology, PalletRunnerGTR revolutionizes the way you manage spaces, offering an unparalleled experience.

THE PalletRunnerGTR MODELS

Available in 20 standard models: each model is specific to a type of pallet/load unit to be handled.

PalletRunnerGTR is a shuttle compatible with other brands, including: Jungheinrich, Toyota, SSI Schäfer, Mecalux, Stow. But that’s not all! We can customize PalletRunnerGTR according to your needs.